Do you want to know about air header distribution manifolds? Are you in a dilemma about what it is and what its uses are?

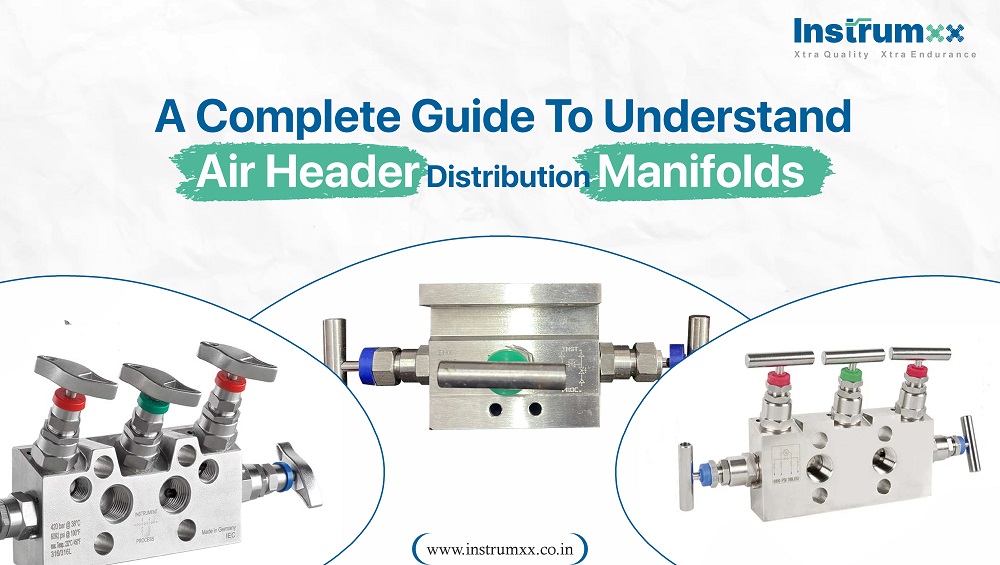

The distribution manifolds, often referred to as air and steam headers, allow a single gas, air, or liquid supply line to be diverted to a number of locations or equipment. They are also used to remove surplus liquid or condensation from vent valves before corrupting the working equipment. Air manifolds offer a variety of connecting possibilities for isolation.

Additional information!

The actuators on pneumatic instruments, including steam flow meters, pressure controllers, and valve positioners, get air through air headers from the compressor. These manifolds are authorized for low-pressure applications up to 1000 psi (threaded or flanged end connections). They are commonly used in industrial pulp and paper, chemical processing, oil and gas, and energy sectors.

Usually have many outlets with ball valves installed for isolation. A drain valve (like the one in the accompanying picture) can be fitted at the bottom to routinely release condensed water from the headers in order to prevent water from entering the pneumatic instrument when compressed air or steam.

How to choose the best Air Header Distribution Manifolds?

Essential details for selection:

- Conditions for connecting to the Flare header

- Size and kind of the connection

- Is an intake valve necessary?

- Outlet volume? Is an output valve necessary? Or a plug-in valve?

- Is a vent port for the atmosphere necessary? And is a plug or valve needed?

- Do you need a mounting bracket?

- Sewer or a drain

Why use air headers?

To distribute a single air source to several pipes, air headers or distribution manifolds are typical air source distribution components. Distribution manifolds are produced from bars and air headers from the tubing.

A pipeline transports fluids to the air headers, where they are subsequently dispersed to every single instrument. Threads or flanges at the inlet ports link with air sources.

The most common uses of air headers are in the chemical, pharmaceutical, electric power, and textile sectors because of their benefits, including quick assembly, straightforward operation, low maintenance requirements, and cost-effectiveness.

Materials used for air header distribution manifolds

Carbon steel and stainless steel are the two materials that are utilized for manifolds most frequently. The most durable and long-lasting material we can choose is stainless steel, while carbon steel is the most affordable. Due to its fragility, we do not recommend utilizing metal for air manifolds.

Why are air header distribution manifolds prepared?

The Air Manifolds are set up to accommodate various outlet valves. A typical FDH will deplete on the opposite end of the valve and have a bay toward one side.

To provide the best selection for our consumers, we also examine the product's quality from many angles. A variety of end associations are possible for the Gulf association. There are several outlets and valves on either side of the tank and a channel in the center.

Conclusion

I hope you understand the above explanation regarding the air header distribution manifolds. Now you know about it in detail.

+91 9820101803

+91 9820101803